Facilities

Manufacturing Facility and Process

Melting Furnaces

4 numbers , 1 ton each, Inductotherm melting furnances are available.

- One pair of dual track Inductotherm Furnace

- One pair of mono-track Inductotherm Furnace

Moulding Machine

- Two pair Arpa-450 Disa make moulding machine

- Size: 600 mm by 700 mm by 500 mm (height)

Core making

One number Compex make cold box core shooter machine of capacity 15 kgs.

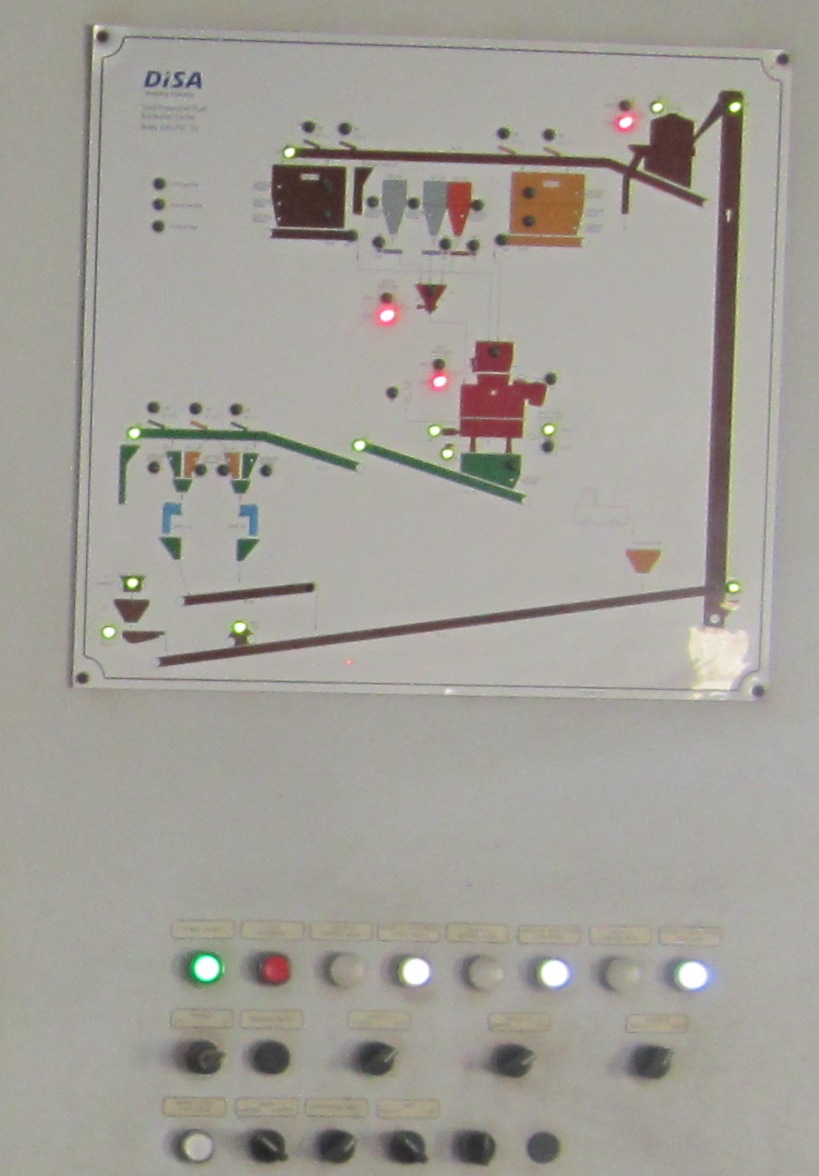

Sand Plant

PLC controlled Disa make centrifugal sand mixture and two numbers sand storage hopper

Liquid Metal Pouring

Laddles of capacity 1000 kgs each with Laddle Pre- Heater

Shot Blasting

- 2 number closed loop Disa make Shot Blasting Machine

- 1 number Y- type Shot Blasting machine

Heat Treatment Facilities # 1

Bogie Hearth Furnace:

Electrically heated bogie hearth furnace of capacity 5000 kgs. per batch for Normalizing and Annealing.

Heat Treatment Facilities # 2

- Hardening and Tempering Furnace – One set Electrically heated

- Hardening and Tempering furnace of capacity 2500 kgs. Per batch.

Heat Treatment Facilities # 3

Hardening and Tempering Furnace – One set hardening and tempering furnace

Pollution Control Facilities

Our company is committed to environment protection and for this purpose we have installed modern pollution control equipments. All facilities like sand plant, melting furnace, shot blasting etc uses latest pollution control equipments.

Plant View